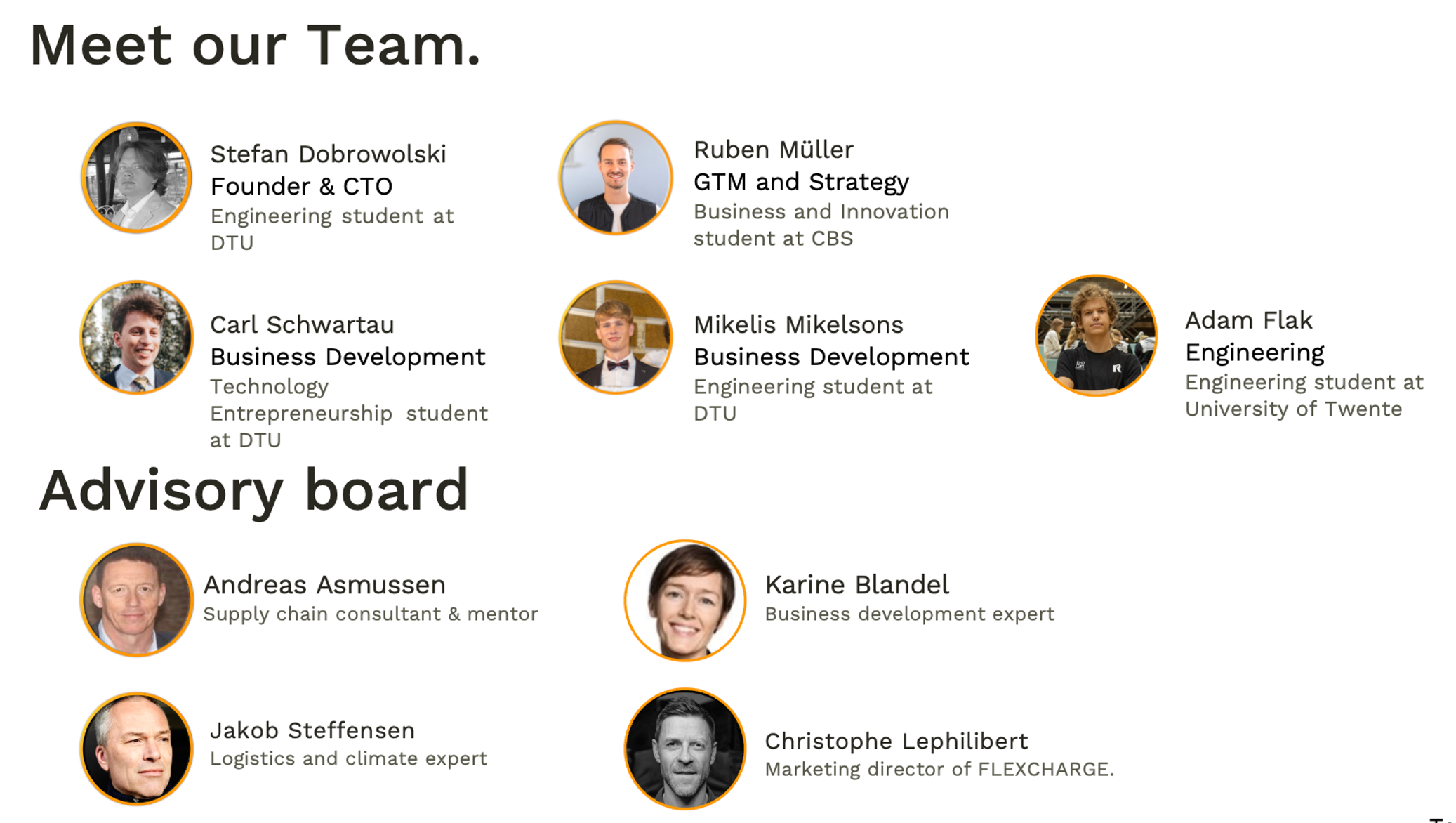

Next Generation Energy Storage

Terminus Energy ApS, Based in DTU, Skylab

The energy transition can only go as far as energy storage systems take it.

Without adequate storage, surplus renewable generation cannot be absorbed by the grid, causing systemic curtailment of up to 15%

Global energy storage capacity must increase 6X by 2030 to align with net-zero goals

Without sufficient storage, blackout risk increases 100X by 2030 as grids destabilise under high renewable penetration

BESS are the state of the art solution but not future-proof.

Batteries lack operational flexibility

Current battery systems are constrained by fixed discharge durations and power-to-capacity ratios. They are optimized for specific use cases - not adaptable to dynamic grid demands or diverse applications.

Battery degradation limits lifespan and performance

Batteries lose capacity and efficiency with every charge cycle. After 10 years, performance declines significantly, driving up lifecycle costs and reducing reliability.

Battery supply chains are dominated by China

Over 90% of the global battery value chain is controlled by China. This dependence creates serious risks for Europe’s energy security, independence, and industrial resilience.

Flywheels are the next generation of

energy storage.

Flexible Discharge

Adjustable discharge times and power to capacity ratio

Wide range of commercial applications

Compact system

Our FESS system is fully modular 10ft container fits into compact on-site or distributed applications

How it works

A flywheel stores electricity as kinetic energy by spinning a rotor at high speed. When power is needed, the motor-generator converts the rotor’s momentum back into electricity

Key principle

Accelerate the rotor → store energy

Decelerate the rotor → deliver energy

Result

Fast response, unlimited cycles,

minimal efficiency loss

European value chain

No lithium or rare-earth materials are required European-sourced components for a resilient, independent value chain

Long lifespan

25 years of lifetime with no performance degradation

Much lower levelized cost of storage compared to BESS.

While most FESS startups focus on short-term balancing, we’re building the first flywheel for daily energy storage as a true alternative to BESS

Our flywheel combines proven engineering with advanced materials.

Our innovation

We redesigned the traditional flywheel with modern materials as a mechanical battery.

Optimized with:

Hybrid magnetic bearings → eliminate friction and mechanical wear.

Advanced rotor material:

low alloy ultra high strength steel → high strength, low cost

Stacked sheet steel rotor structure → lightweight, modular

Result

No mechanical contact. Minimal losses. 25+ year lifetime.

We rethink FESS application and can compete with BESS.

| Specification | Terminus Energy | BESS |

|---|---|---|

| Price ($/kWh) | 70–110 | 110 |

| Lifespan (years) | 25 | 10 |

| LCOS | Low | High |

| OpEx | Low | High |

| Specification | Terminus Energy | BESS |

|---|---|---|

| Discharge time (hours) | 0.5–8 | 2–4 |

| Self discharge rate | 0.25% / hour | 0.3–2% / day |

| Roundtrip efficiency | >90% | 81–88% |

| Response time (ms) | 250 | 750 |

The long lifespan of FESS is enabling low LCOS and OpEX.

The technical specs of FESS are significantly more agile and flexible.

There are multiple high-growth markets to enter

Enables ultra-fast charging anywhere, even with limited grid capacity

Generates recurring revenue through grid services

Cuts operational costs for CPOs by reducing peak demand charges

High Power Charging

CAGR: 27.5%

Powers high-speed charging for fleet and logistics hubs

Optimizes energy costs through on-site buffering and grid support

Adds ancillary service revenue when vehicles are idle

Depot Hub Charging

CAGR: 28.6%

Unlocks multiple revenue streams via energy arbitrage and ancillary services.

Balances renewables and stabilizes grid frequency.

Utility Energy Storage

CAGR: 30%

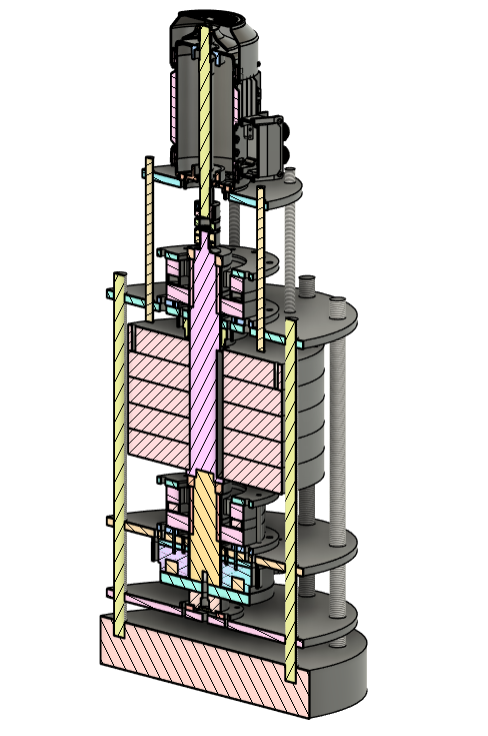

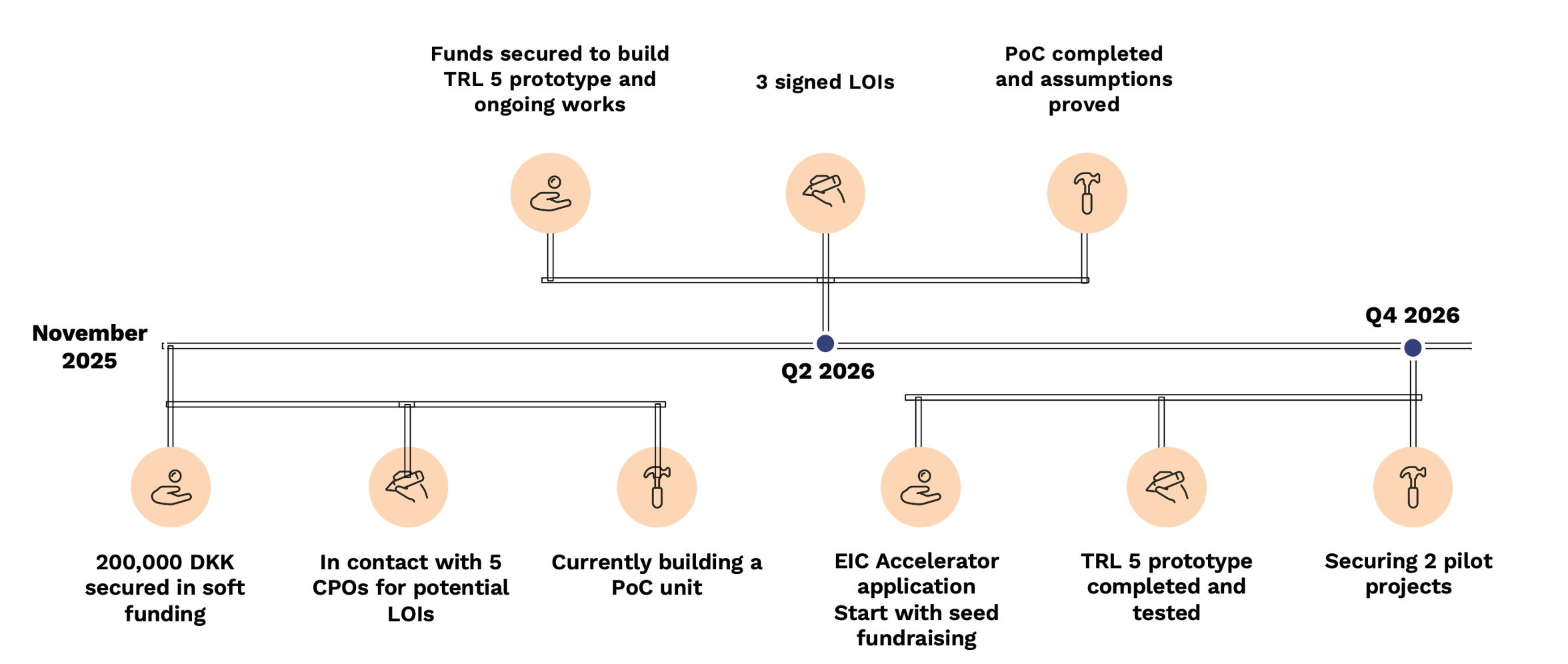

We are currently building our PoC unit to prove that our system works.

Our Proof of Concept focuses on testing the most critical part of a FESS - the magnetic bearing system.

The PoC is designed to most efficiently test the bearings with a 1% scale rotor of 300 kg.

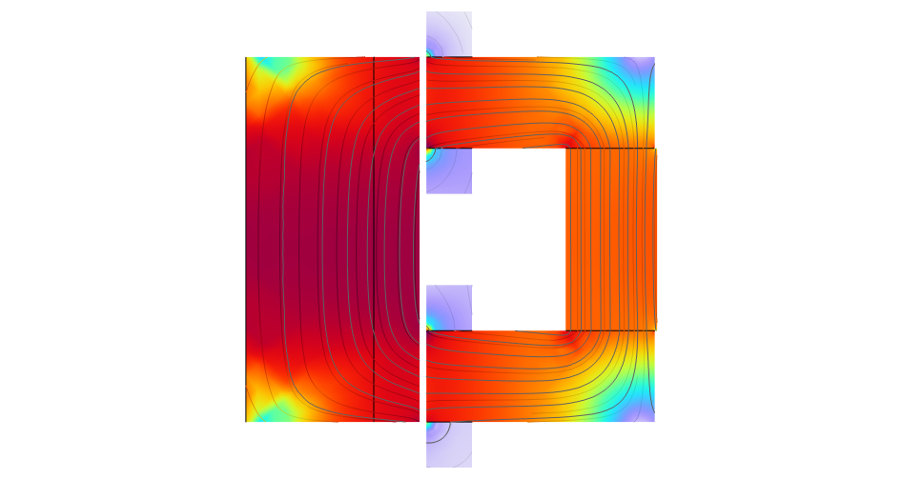

The simulation of magnetic field flux lines in a radial magnetic bearing. This is the most critical component to prove for a heavyweight flywheel.

*simulation of magnetic field flux lines in radial magnetic bearings

And then we will build a working pilot.

*rendering of the PoC unit